Spray a fast test pattern on a clean sheet of paper and check the consistency of the particle size. Talked with Dan in the Ballard store and he was more than helpful.

Spray Gun Beginner S Guide 13 Steps Instructables

Inspect side seals and mix chamber for scratches Replace.

. Unable to Get Round Spray Spreader screw not seating properly clean or replace the spreader screw Air cap retaining ring is loose tighten appropriately Will Not Spray No air pressure at the spray gun increase air pressure check air passage for any obstruction Fluid Adjustment Needle needs opened Fluid too heavy for gravity or suction feed Increase fluid. Very friendly and helpful. The spray gun is a key component to achieving an excellent Teflon paint or powder coating finish but spray guns are far from maintenance-free.

Clean or replace tip. I have and old spray gun and could not find parts for it on the Internet. Clean with soft implement or submerge in suitable solvent and wipe clean.

Gun delays then actuates abruptly. Spray a fast test pattern on a clean sheet of paper and check the consistency of the particle size. First make sure that your tip size is the right size.

Tighten retaining ring until bottomed out. If one of the air passages become plugged the spray pattern is not going to spray evenly. Retaining ring not bottomed out.

Using a spray gun can give you a smooth as silk surface finish. Remove and clean air cap. Cured material around side seals.

Troubleshooting Common Spray Gun Issues. Clean or replace mesh filter. Tighten fluid nozzle or replace fluid nozzle and needle.

Ad Great prices free shipping over 80 sales support available. Adjust Spray Pattern 1. Then watch to see the formation of the run-outs of material across the full width of the spray pattern.

Tip adjusted too wide. Too much or too little pressure for your tip size and materials can also negatively affect your spray patterns. Turn the atomizaton air to about 30 psi at the gun.

Paint sputters from gun. Cleaning your spray gun regularly is important to avoid slowdownsor stoppagesin production. Bad spray patterns can be caused by several different things.

HVLP Spray Gun Problem 2 My Gravity Gun is not getting any paint delivered to it If you are using a gravity feed HVLP spray gun and not getting any paint in your pattern this is most likely due to needing to thin your paint needing a larger fluid nozzle or needing to use a system that will force the material to the spray gun like a Dekups. To achieve full fan pattern open the air control valve by turning the knob fully coun-terclockwise. This can result in uneven mill thickness stripes and dry edges.

If your HVLP spray gun is spraying inconsistent patterns ie. The gun was from the 1970s but he was still able to find me a parts list for it. This will highlight how well the material is distributed.

Having examined the vertical spray pattern for uniformity of shape and size now turn the air cap through 90o and static spray a horizontal pattern making sure you trigger for long enough to load the shape with material. Airless gun will not spray. Its perfect for doing faux metal or even just painting a straight color really fast.

Increase or decrease the air pressure until even particle size is achieved. ProblemTear drop or oval shaped spray pattern. Lubricate or replace packings or tighten packing nut.

To create a round pattern turn the pattern air off by turning the air control valve fully clockwise. Dirty or plugged air cap holes. SOLUTION Adjust fluid regulator or fill fluid supply.

Thin per manufacturers recommendation. Spray tip partially plugged. Spray pattern has tails or fingering.

Rotate the air cap to achieve desired spray pattern. Shop online or call today. Tighten or replace fitting.

Next make sure youre using the right amount of pressure. If your paint gun is spitting or dripping paint it is probably because the nozzle is. HVLP Spray Gun Problems HVLP Spray Pattern Problems.

Spray a horizontal test pattern holding the trigger open until the material begins to run. Hats off to Dan S. Turn the atomizaton air to about 30 psi at the gun.

A tip thats too large will cause issues with your painting pattern. Air cap clogged at fluid needle orifice. But it can be a bit intimidating as a beginner.

Orange peel check the. Insufficient material in cup material not filtered fluid nozzle loose needle Teflon packing damaged needle. Spray a horizontal test pattern holding the trigger open until the material begins to run.

Increase or decrease the air pressure until even particle size is achieved. When I was first starting out I couldnt find any. Increase pressure at pump.

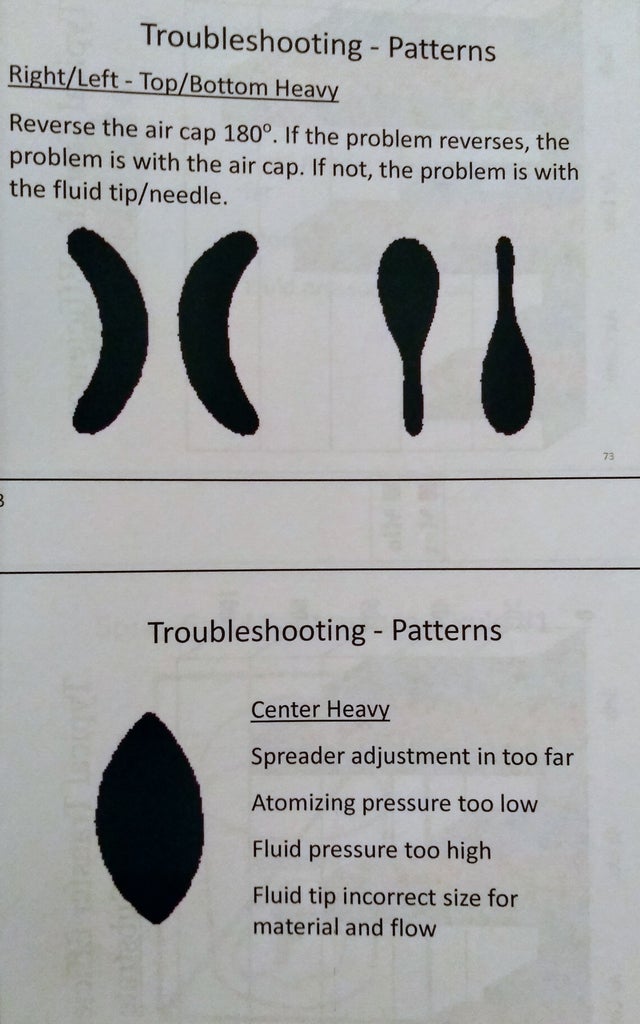

If the pattern is heavy on one side or if the spray gun is spraying a half moon shape turn the air cap 180 degrees and see if.

Devilbiss Hand Spraygun Troubleshooting

Techniques For Painting With A Sprayer Graco Homeowner

What To Do If Your Spray Gun Clogs Technical Column Fuso Seiki Co Ltd

Auto Paint Sprayer Spray Gun Controls Car Paint Technologies Guangzhou Jinwei Chemical Co Ltd

0 comments

Post a Comment